Amazon changed everything. Two-day shipping went from premium to expected. Now customers expect same-day, next-day, and real-time tracking as baseline experiences. Every day your fulfillment lags behind competitors is revenue walking out the door.

Order fulfillment automation closes this gap. By transforming manual pick-pack-ship operations into streamlined, verified workflows, you can process 10x more orders with the same staff, ship faster, and make fewer mistakes.

This guide shows you exactly which order fulfillment processes to automate, the measurable benefits you can expect, and how to implement automation that scales with your growth.

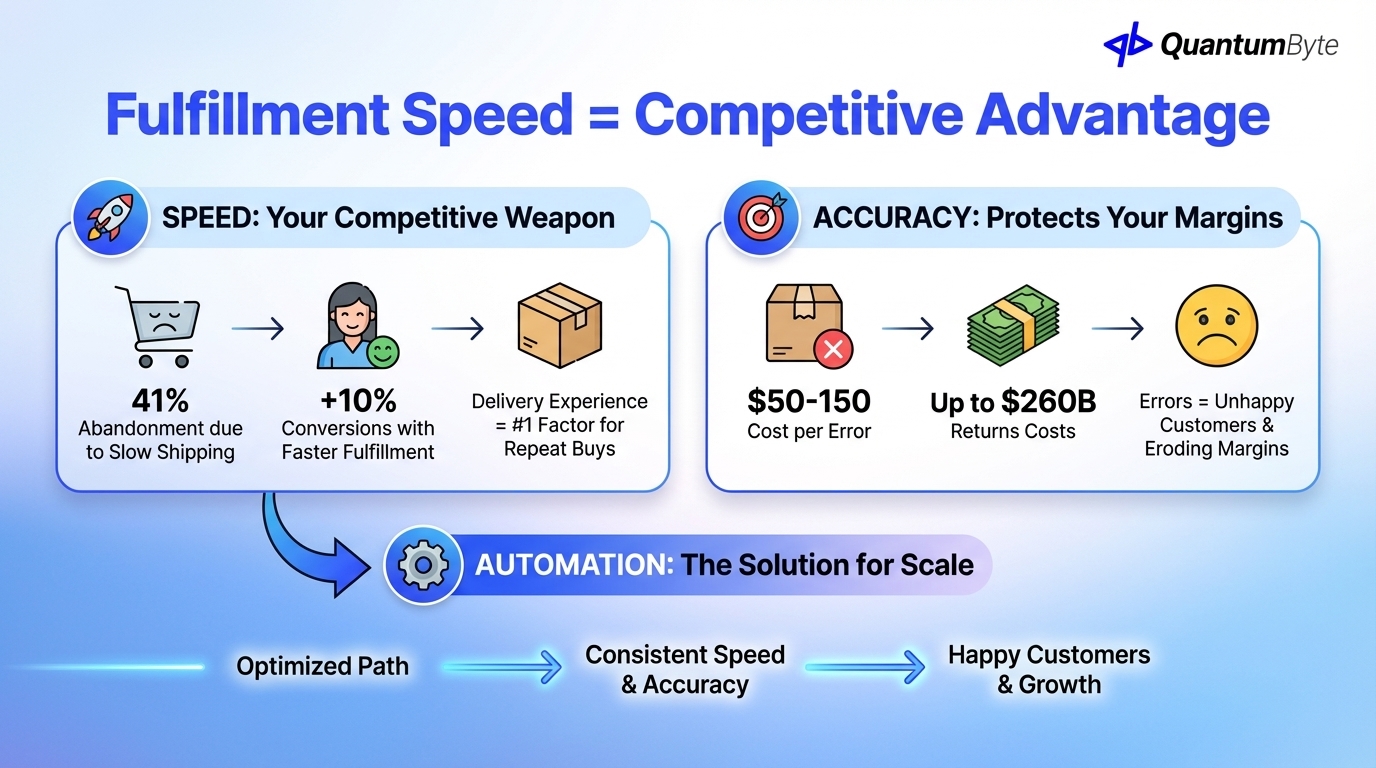

Fulfillment Speed as Competitive Advantage

Fulfillment isn't a cost center, it's a competitive weapon.

The speed imperative:

- Up to 41% of online shoppers abandon carts due to slow shipping options (no same day delivery)

- McKinsey research shows that faster fulfillment can improve conversions by up to 10%

- Delivery experience is now the #1 factor in repeat purchases

The accuracy imperative:

- Wrong shipments cost $50-150 each in returns, replacements, and goodwill

- Supply Chain Dive reports costs of up to $260B to support return purchases.

- 1 error per 100 orders = unhappy customers and eroding margins

Manual fulfillment can't deliver speed and accuracy at scale. Automation solves this by making every order follow the same optimized path.

The Order Fulfillment Workflow

Understanding the full workflow reveals automation opportunities:

Order Received → Validation → Inventory Allocation → Pick → Pack → Ship → Track → Deliver

Where Manual Processes Break Down

| Step | Manual Friction | Order Fulfillment Automation Solution |

|---|---|---|

| Order Received | Manual entry from multiple channels | Auto-import from all sources |

| Validation | Manual review of each order | Rule-based auto-validation |

| Allocation | Checking availability, manual holds | Real-time inventory lock |

| Pick | Finding items, paper lists | Optimized digital pick lists |

| Pack | Guessing box sizes, manual labels | Guided packing, auto-labels |

| Ship | Manual carrier selection | Automated best-rate selection |

| Track | Customer inquiries, manual lookups | Proactive notifications |

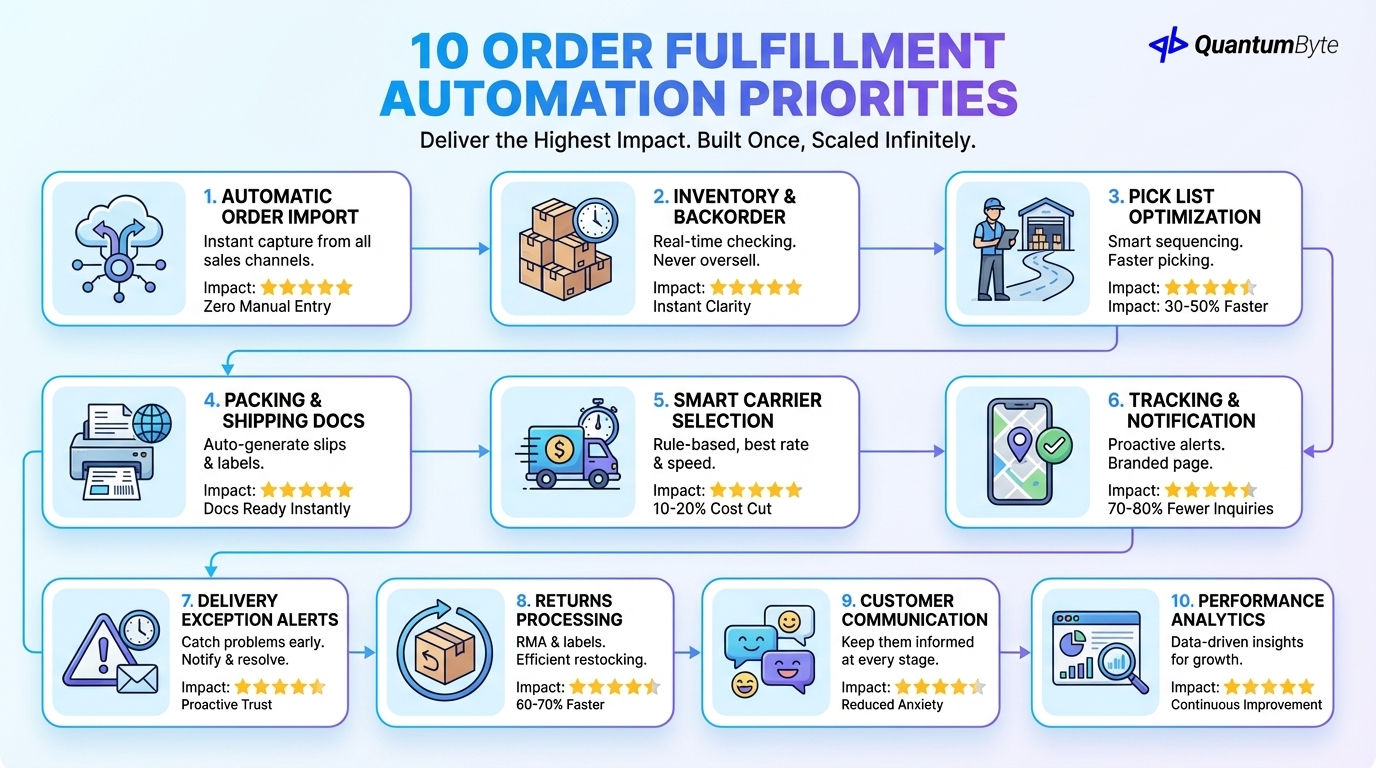

10 Order Fulfillment Automation Opportunities

These automations deliver the highest impact:

1. Automatic Order Import from All Sales Channels

Stop manual order entry from website, Amazon, eBay, and wholesale orders.

What to automate: Real-time order capture from e-commerce platforms, marketplace synchronization, order normalization to standard format.

Impact: Zero manual entry. Orders flow instantly from sale to fulfillment queue.

2. Inventory Allocation and Backorder Management

Never oversell. Never fail to communicate delays.

What to automate: Real-time inventory checking, automatic allocation, backorder handling with customer notification, allocation priority rules (FIFO, customer tier).

Impact: Overselling eliminated. Customers informed instantly of any delays.

3. Pick List Generation and Optimization

Transform random walking into efficient picking.

What to automate: Pick list generation with optimal path sequencing, batch picking for multiple orders, wave picking for high-volume periods.

Impact: 30-50% faster picking. Reduced warehouse travel time.

4. Packing Slip and Shipping Label Automation

Eliminate manual document creation.

What to automate: Packing slip generation, shipping label creation with rate shopping, box size recommendation, international documentation.

Impact: Documents ready instantly. Zero manual data entry.

5. Carrier Selection Based on Cost/Speed Rules

Always choose the optimal carrier without manual comparison.

What to automate: Real-time rate comparison, rule-based selection, delivery date verification, carrier performance tracking.

Impact: 10-20% shipping cost reduction.

6. Tracking Number Capture and Customer Notification

Proactive communication eliminates "where's my order?" calls.

What to automate: Automatic tracking capture, customer notification emails, branded tracking page, delivery milestone notifications.

Impact: "Where's my order?" inquiries reduced by 70-80%.

7. Delivery Exception Alerts and Resolution Workflows

Catch problems before customers notice.

What to automate: Exception detection, automatic alerts, proactive customer notification, resolution workflow triggers.

Impact: Problems addressed proactively. Customer trust maintained.

8. Returns Processing and Restocking

Returns are inevitable. Manual returns processing is not.

What to automate: RMA generation, return label creation, inspection workflow, inventory restock routing, refund processing.

Impact: Returns processing time reduced 60-70%.

9. Customer Communication Automation

Keep customers informed at every stage.

What to automate: Order confirmation, processing updates, shipping notification, delivery confirmation, post-delivery follow-up.

Impact: Customer anxiety reduced. Support load decreased.

10. Performance Reporting and Analytics

Know what's happening. Improve continuously.

What to automate: Daily fulfillment dashboard, order cycle time tracking, error rate monitoring, carrier comparison.

Impact: Data-driven decisions. Continuous improvement.

Speed and Cost Benefits

Let's quantify the returns from order fulfillment automation:

Order Processing Time: 15 min → 5 min

Manual process: Order review (2 min), data entry (3 min), pick list creation (2 min), picking (5 min), packing (2 min), label creation (1 min) = 15 minutes

Automated process: Auto-import, auto-validation, optimized pick (3 min), guided pack + auto-label (2 min) = 5 minutes

Labor Savings: Process 10x Orders with Same Staff

| Orders/Day | Manual Staff Needed | Automated Staff Needed |

|---|---|---|

| 50 | 2 | 1 |

| 100 | 4 | 1 |

| 200 | 8 | 2 |

| 500 | 20 | 4 |

At 500 orders/day, automation saves 16 full-time employees, over $600,000 annually in labor costs.

Shipping Cost Optimization: 10-20% Savings

Automated rate shopping compares all carriers in milliseconds, applies business rules, captures volume discounts.

Example: $200,000 annual shipping × 15% savings = $30,000

Error Reduction: 95% Fewer Wrong-Item Shipments

Manual picking has 1-3% error rates. Automated verification reduces errors to <0.1%.

Cost per error: Return shipping ($15) + replacement shipping ($15) + labor ($20) + goodwill = $50-75+ per error

Total Impact Summary

| Benefit | Annual Value |

|---|---|

| Labor savings (processing time) | $86,667 |

| Shipping optimization | $30,000 |

| Error reduction | $37,500 |

| Support cost reduction | $14,000 |

| Conversion improvement (2 days faster) | $120,000 |

| Total Annual Benefit | $288,167 |

| Implementation Cost | $20,000-40,000 |

| Payback Period | 1-2 months |

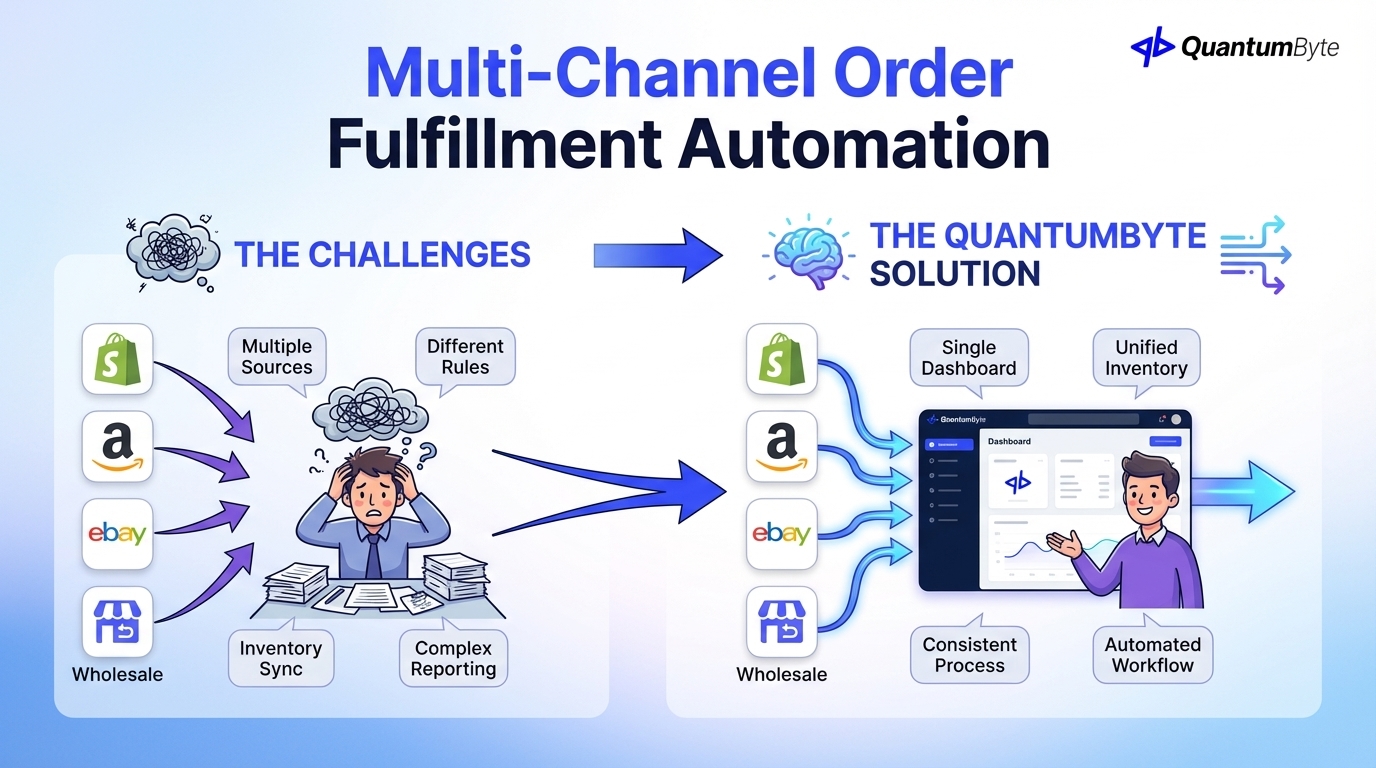

Multi-Channel Order Fulfillment Automation

Modern businesses sell everywhere. Order fulfillment automation must keep up.

Challenges of Multiple Sales Channels

Selling on Shopify + Amazon + eBay + wholesale creates:

- Multiple order sources requiring aggregation

- Different fulfillment requirements by channel

- Inventory synchronization challenges

- Complex reporting across channels

Unified Order Management

The solution: consolidate all orders into one fulfillment workflow with single dashboard, unified inventory view, and consistent process regardless of source.

Building Your Order Fulfillment Automation System

QuantumByte develops custom fulfillment apps that streamline your order workflows:

Pre-Built Integrations with Major Platforms

E-commerce: Shopify, WooCommerce, Magento, Amazon, eBay

Carriers: UPS, FedEx, USPS, DHL

Accounting: QuickBooks, Xero

Custom Workflows for Your Unique Process

Every order fulfillment operation has unique requirements: special handling, custom packaging rules, specific carrier preferences, industry-specific documentation.

Custom automation accommodates these rather than forcing generic processes.

Mobile-First for Warehouse Operations

- Native mobile apps for iOS and Android

- Optimized for scanning and quick actions

- Offline capability for connectivity gaps

Scalable from 10 to 10,000 Orders/Day

- No per-order pricing that punishes growth

- Performance designed for scale

- Add capabilities as you need them

Conclusion: Build Order Fulfillment Automation as Competitive Advantage

In the Amazon era, order fulfillment speed and accuracy separate winners from also-rans. Customers expect:

- Fast shipping with accurate promises

- Real-time tracking throughout

- Error-free delivery

- Easy returns when needed

Manual fulfillment can't deliver this at scale. Order fulfillment automation can.

The path forward:

- Audit your current fulfillment: Where are the bottlenecks and errors?

- Calculate your opportunity: Use the formulas above to quantify potential gains

- Prioritize quick wins: Start with highest-impact automations

- Build for scale: Choose solutions that grow with you

Every day you delay, competitors with automated fulfillment capture customers expecting better experiences.

Ready to transform your fulfillment operations? Schedule a consultation to explore your specific automation opportunities.

Other Guides to Explore

- Supply Chain Automation: How to Reduce Costs and Increase Revenue

- Warehouse Management System for Small Business: Complete Guide

- Inventory Management Automation: Reduce Stockouts and Increase Sales

- How to Automate Business Processes to Increase Revenue in 2025

Frequently Asked Questions (FAQ)

How much does order fulfillment automation cost?

Basic shipping software runs $50-200/month. Custom order fulfillment systems typically cost $15,000-50,000 for development plus ongoing maintenance. Most implementations achieve payback within 2-4 months.

Can I automate fulfillment if I sell on multiple platforms?

Yes. In fact, multi-channel selling is where automation becomes essential. Unified order management consolidates orders from all channels into one fulfillment workflow.

How long does order fulfillment automation take to implement?

Basic shipping automation can be live in days. Comprehensive custom systems typically take 4-8 weeks from requirements to full production.

What order volume justifies order fulfillment automation?

Even businesses processing 20-30 orders/day see meaningful benefits. Calculate your specific ROI using the formulas above.

How do I handle same-day and next-day shipping requirements?

Same-day fulfillment requires compressed workflows and automation to eliminate manual delays. The key is reducing order-to-ship time from hours to minutes through end-to-end automation.